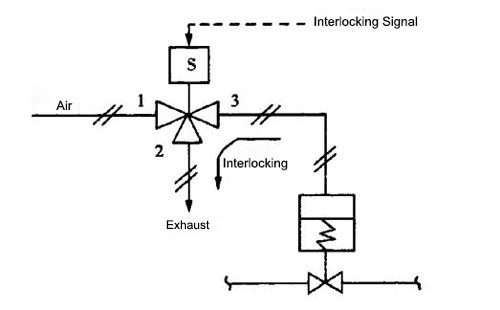

Used to operate single acting cylinders or as a simple device to blow air. These valves create one action such as extending a cylinder.

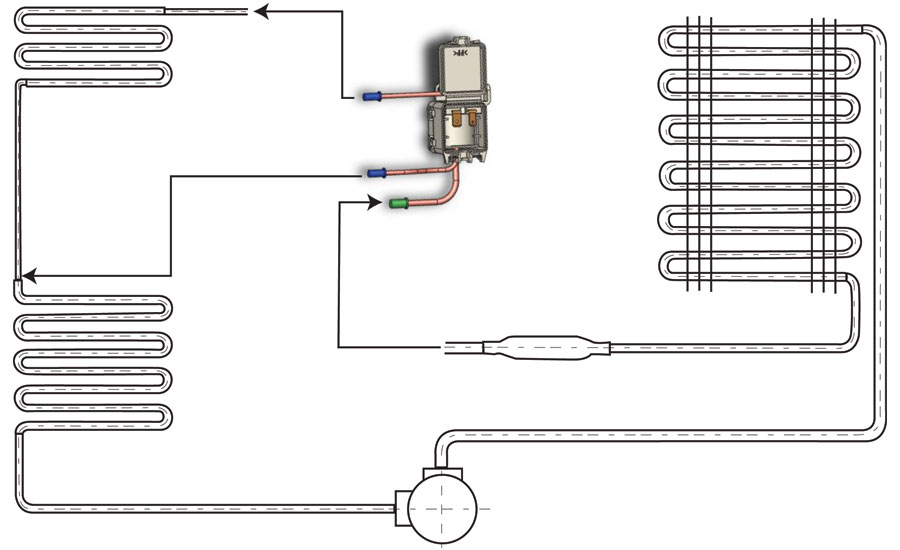

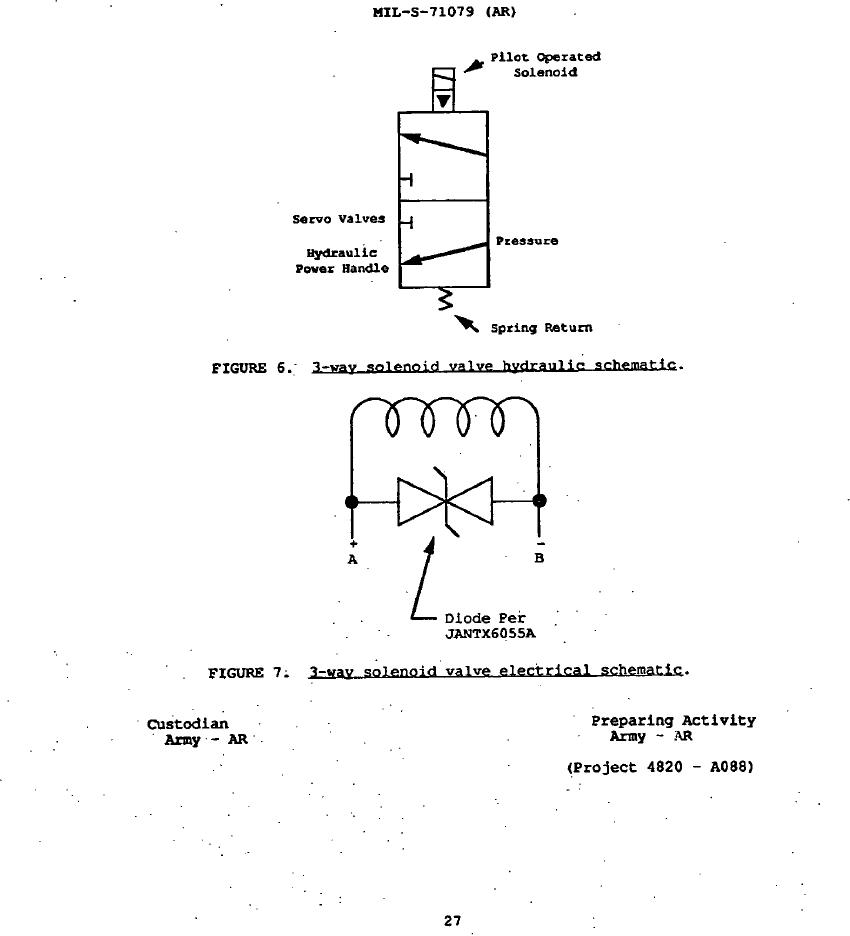

Figure 6 3 Way Solenoid Valve Hydraulic Schematic

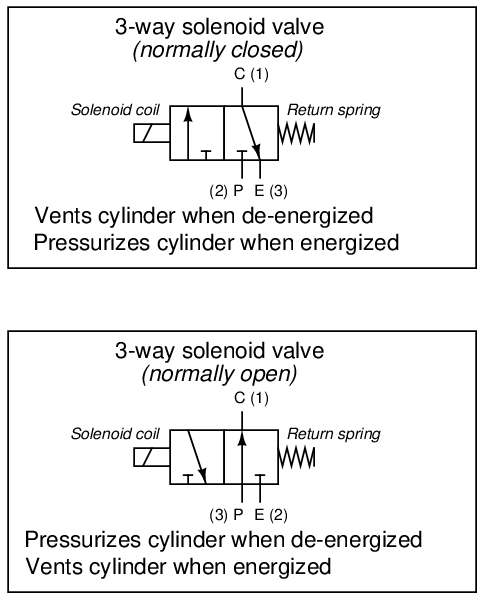

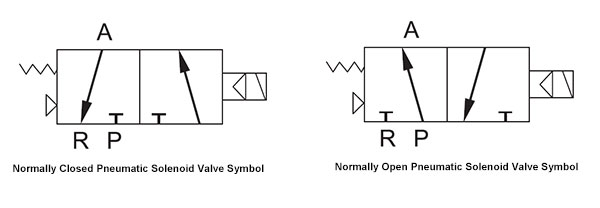

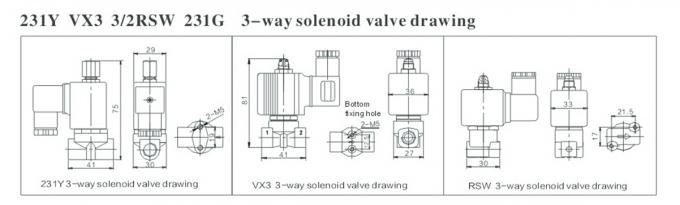

3 way solenoid valve diagram. Energizing the valve raises or lowers the plunger. 3 way directional control solenoid valves. In a multi valve set up a manifold can replace the valves body but provides the same function. 3 way solenoid valves have three ports for fluid and like 2 way valves may be referred to either as normally open and normally closed. A 3 way directional control solenoid valve has 3 pipe connections. 3 ports air in from compressor usually marked p air out to device usually marked a exhaust out usually marked ea.

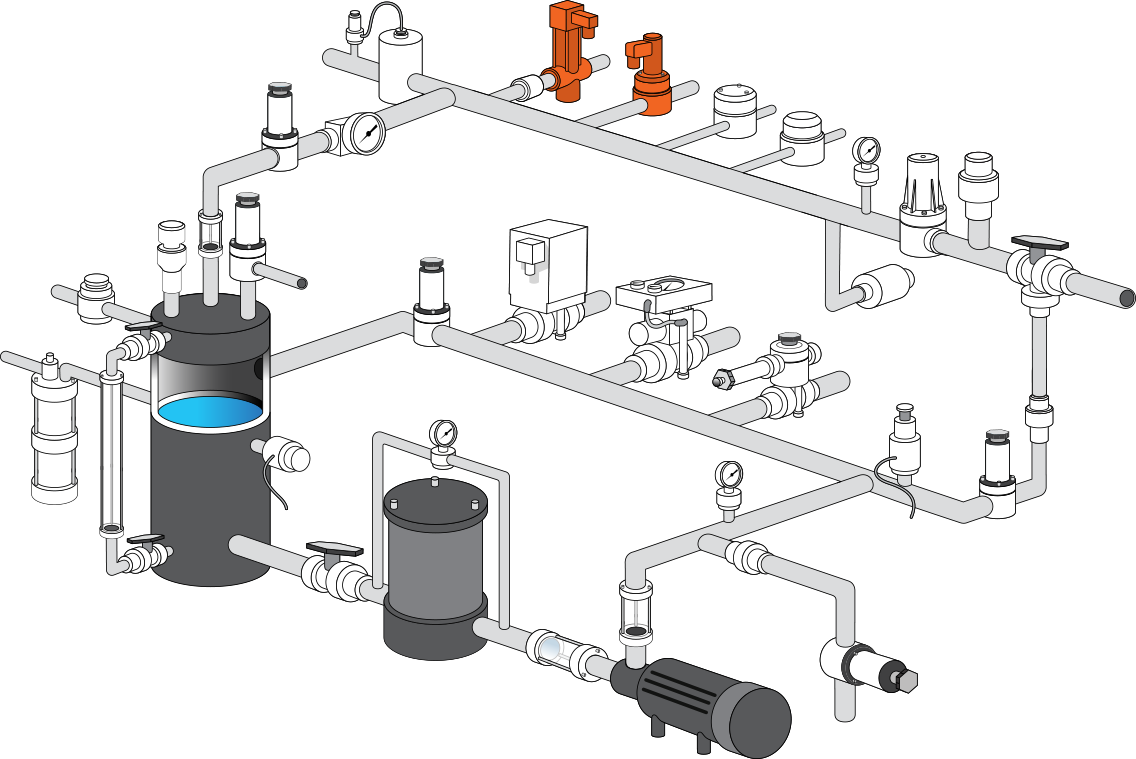

These 2 way 3 way and 4 way solenoid valves can handle most fluid control applications and are now available with class i division 2 approvals we also offer a complete line of general service isolation pinch proportional valves and manifold assemblies for use in medical equipment analytical instrumentation and industrial applications. In figure 2b a 3 position valve the valve has both solenoids and spring return actuators on both sides the spring return actuators will return the valve to the center position but only if neither of the solenoids is active. Driving pneumatic actuators blow off pressure release and vacuum applications. A valve can only be in one position at a given time. With two paths for flow sharing one common terminal. A 52 way valve can be used as a 32 way valve by only using only one inlet and the corresponding outlet port.

The body has an inlet and an outlet port allowing media to flow through the. Solenoid control valves that change valve position openclose etc by direct movment from a solenoid are called direct acting. Ports on a pneumatic 3 way valve are commonly labeled with the letters p e and c. Two 2 way or three 3 way valve operation. Also known as 3 way and 32 valves they direct airflow from the inlet to your equipment and exhaust return airflow to create motion. 32 way valves are suitable for several tasks.

3 way solenoid valves operate in a manner analogous to single pole double throw spdt electrical switches. With two 22 way valves the function of a 32 way valve can be mimicked. The same diagram could be drawn using the triangle solenoid valve symbols rather than the block symbols more common to fluid power diagrams. Apply voltage to the electrical connection to actuate. The following diagram shows a 4 way solenoid valve connected to the piston actuator of a larger process ball valve. The body orifice and the stop orifice one of which is always open.

In the off position they exhaust air from the system allowing equipment to reset so the action can be repeated. The cavity port the body orifice port and the stop port. Hook up supply air to inlet when power is applied solenoid opens and air release out of outlet. This allows for 2 paths of flow. Every solenoid valve has a number of standard components including electrical coil a plunger and spring seals and a body. Solenoid control valves that change position openclose etc by opening small pilot circuits allowing pressurised air fluid or gas to move the valve are called pilot operated or servo pressure assisted valves.

It has 2 orifices.