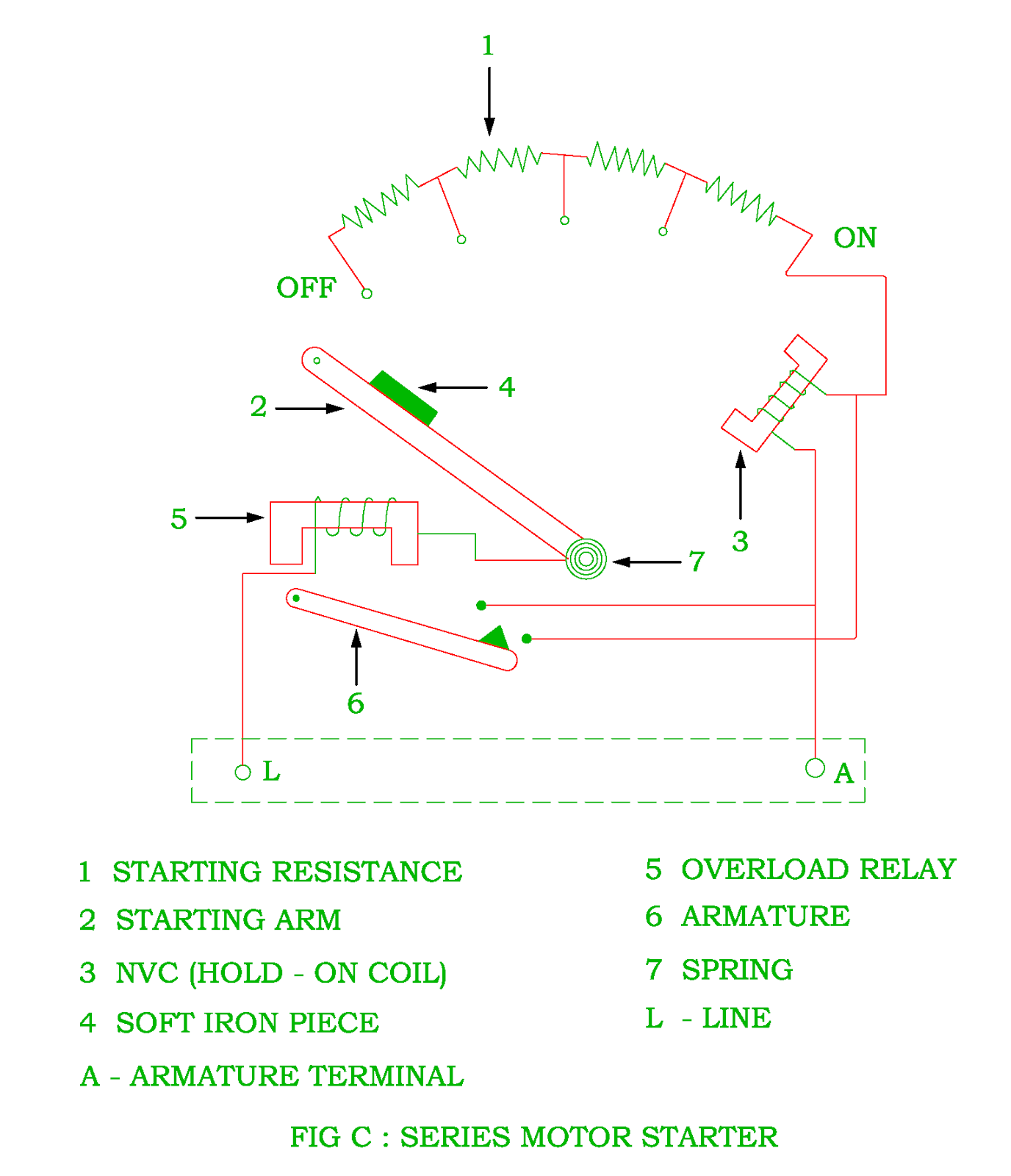

The electromagnet that holds the starter in the run position is in the field circuit. A starter is not necessary for a 6v or 12 v dc motor and it can be run directly.

Dc Motor Starting Methods Electrical Industrial

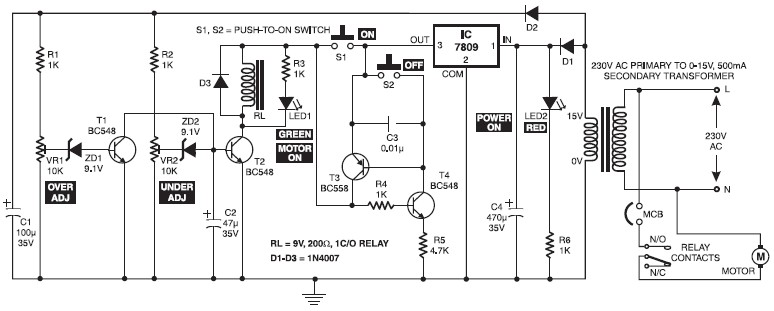

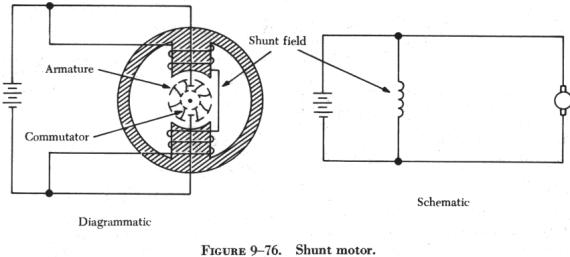

Dc motor starter diagram. A 3 point starter is a device that helps in the starting and running of a dc shunt motor or compound wound dc motor similar to a 4 point starter. Dc motor starters allow a dc motor or motor controlled device to be turned on or off. Dc motor starters to avoid the above dangers while starting a dc motor it is necessary to limit the starting current. The introduction of dc motors and an electrical grid system to run machinery starting in the 1870s started a new second industrial revolution. This article discusses the construction and working principle of a 4 point dc motor starter. Knowledge of basic single and three phase electrical systems including basic ac and dc motor control and safety measures on electrical equipment.

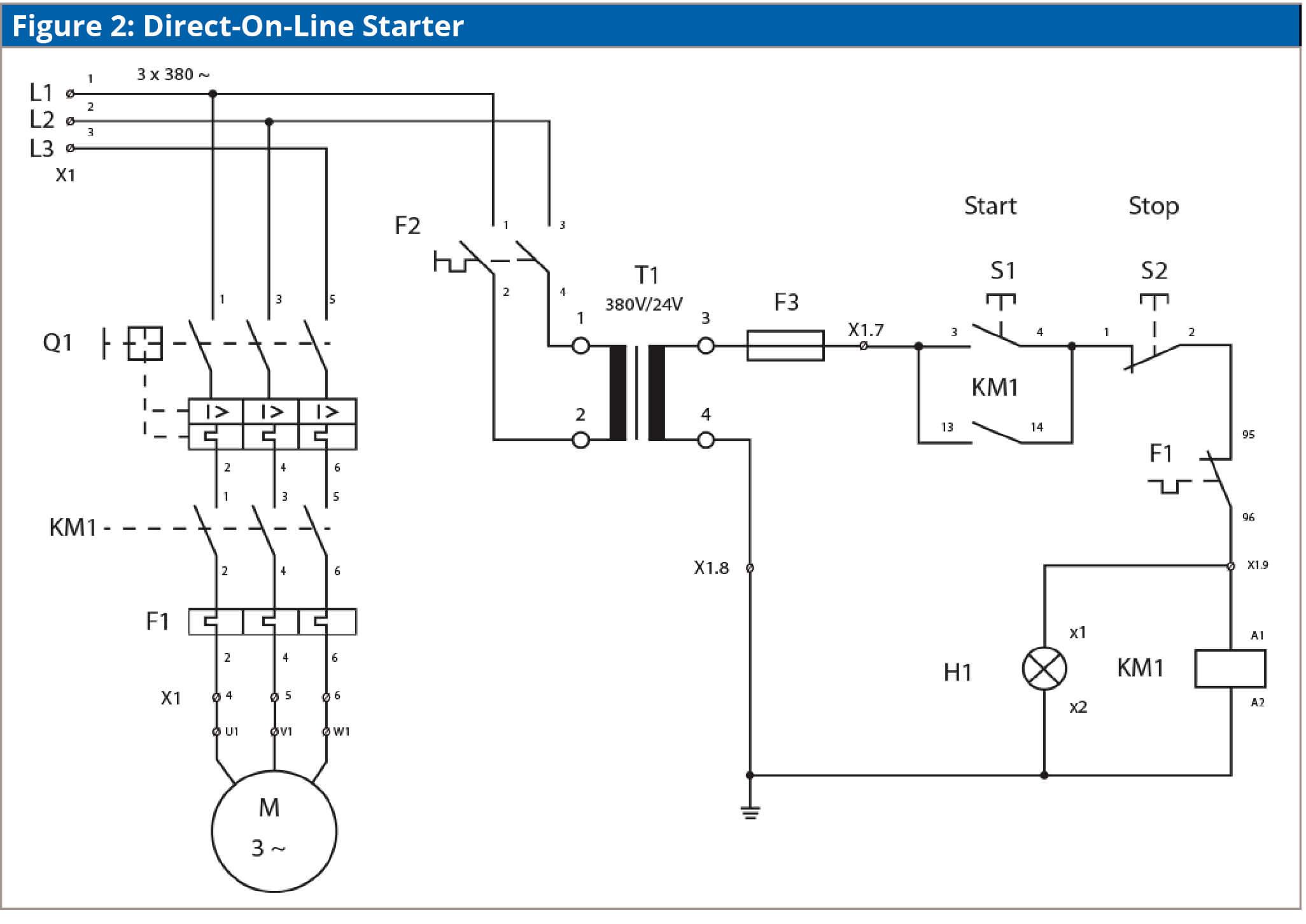

This starter is a so called three point starter. Line voltage control three phase 3ph motor starter controlling a three phase motor rev 08 aug 2006 the above wiring diagram assumes your magnetic starter has a 240v coil. This type of starter can be used for shunt and compound motors and if the field is lost the starter drops out protecting the motor against runaway. So a dc motor is started by using a starter. If you have a 120v coil instead of running a line from coil overload l2 you must run coil overload neutral. A brushed dc electric motor is an internally commutated electric motor designed to be run from a direct current power source.

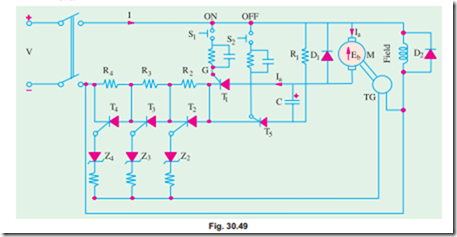

Well its due to the presence of back emf e b which plays a critical role in governing the operation of the motor. Starting a dc motor poses unique challenges. There are various types of dc motor starters such as 3 point starter 4 point starter no load release coil starter thyristor controller starter etc. Three point manual dc motor starter circuit diagram. The primary issue is that dc motors require a large potentially damaging starting current which must be limited by the starter itself. The dc motor was the mainstay of electric traction drives on both electric and diesel electric locomotives street carstrams and diesel electric drilling rigs for many years.

Brushed motors were the first commercially important application of electric power to driving mechanical energy and dc distribution systems were used for more than 100 years to operate motors in commercial and industrial buildings. Now the question is why these types of dc motors require the assistance of the starter in the first place. Figure 1 is a typical wiring diagram for a three phase magnetic motor starter. A 4 point starter protects the armature of a dc shunt motor or compound wound dc motor against the initially high starting current of the dc motor. The 4 point starter has a lot of constructional and functional similarity to a 3 point starter but this special device has an additional point and coil in its construction as the name suggests. Working principle of 4 point starter.

Typical line or schematic diagram. A dc motor starter includes external resistance no volt release coil and overload release coil.