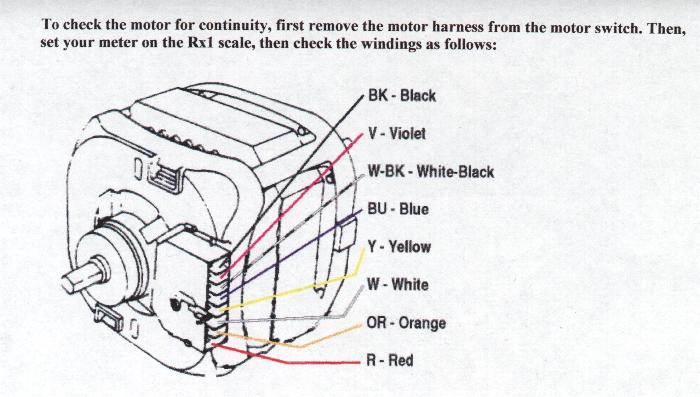

An electronic switch does not respond to the speed of the motor shaft like a centrifugal switch does but has a timed disconnect. Vacuum out the motor so all built up dust and contaminants are removed.

Www Applianceaid Com Images Dir Motor Jpg

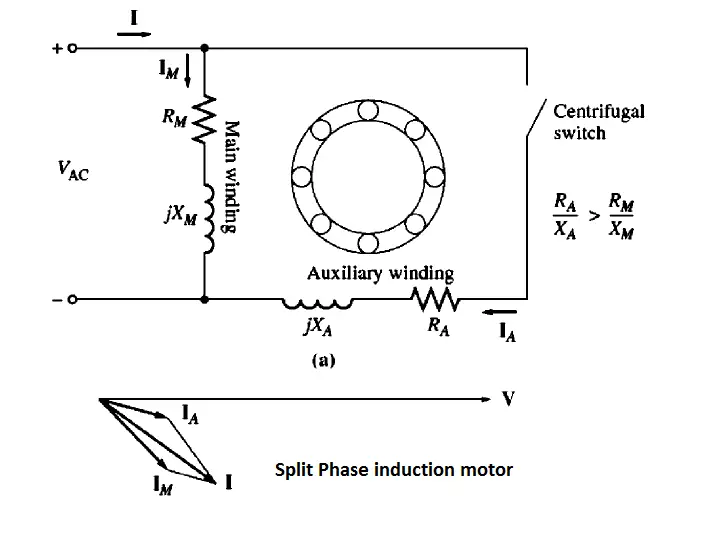

Centrifugal switch diagram. In the below 4 pole motor winding diagram. Smith baldor bluffton motor works leeson electric marathon electric regal beloit corporation torq us. Install the actuator and adjust the switch as described in step 6. The both winding connection shown with power supply acv. Centrifugal switch is connected with starting capacitor and this. A centrifugal switch is an electric switch that operates using the centrifugal force created from a rotating shaft most commonly that of an electric motor or gasoline engine.

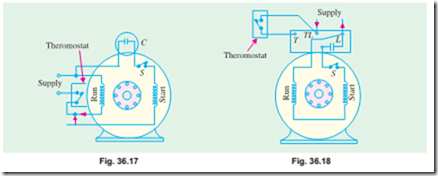

When the motor reaches about 75 of the full load speed the centrifugal switch s opens and thus disconnecting the starter winding and the capacitor from the main winding. Install the new switch and wires at the same locations. Motorsnidec and weg electric. 4 pole induction motor winding diagram with centrifugal switch and capacitors. The main winding connection shown and also the starting winding connection shown. A 1920s patent for.

The centrifugal switch is normally closed and conducts electricity. This opens the switch and breaks the electrical connection. Centrifugal switch replacement and adjustment 5 11. It allows the starting windings to be engaged for 74 seconds and then breaks the circuit. The switch is designed to activate or de activate as a function of the rotational speed of the shaft. It is important to point out from the phasor diagram that the phase difference between im and is is almost 80 degrees as against 30 degrees in a split phase induction motor.

As the motor reaches a certain speed a mechanism in the switch responds to centrifugal force pulling against it. It is also possible to buy an electronic switch to replace the centrifugal switch. This motor is called. When the motor stops a spring pulls the switch mechanism closed again. I have not seen any listed anywhere. Centrifugal switches for electrical applications are essential for the proper functioning of electrical motors.

A centrifugal switch is an electrical switch that operates using the centrifugal force created from a rotating shaft most commonly that of an electric motorthe switch is designed to activate or de activate as a function of the rotational speed of the shaft. Reassemble all components in reverse order of removal. Eis supplies centrifugal switches from top suppliers ao. Capacitor start motor because it uses a capacitor to start itself. A centrifugal switch is used for starting capacitor. Perhaps the most common use of centrifugal switche is within single phase splitphase induction motors.

Make sure that all wires are routed away.