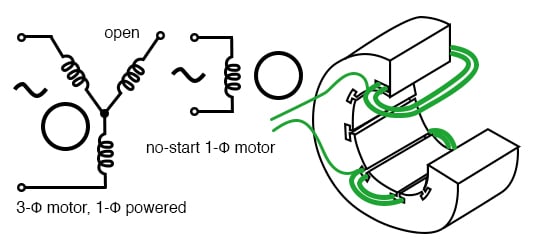

The contact in parallel with the run switch is often referred to as a seal in contact because it seals the momentary condition of the run switch closure after that switch is de actuated. Capacitor run induction motors as seen in figures 10 and 11 are much like the capacitor start induction run with the exception of the start winding and run winding stay in the circuit at all times.

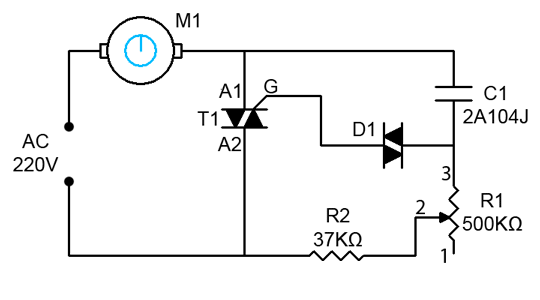

Ac Motor Speed Controller Motor Speed Control Motor

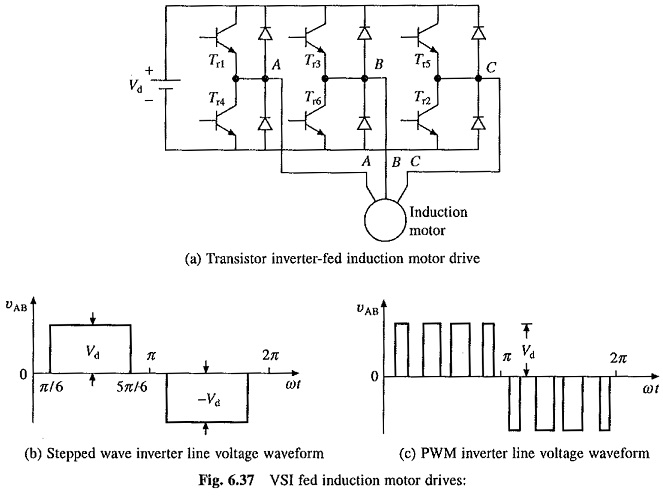

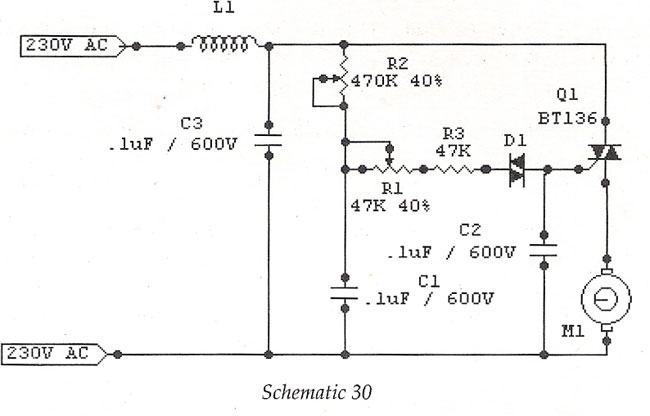

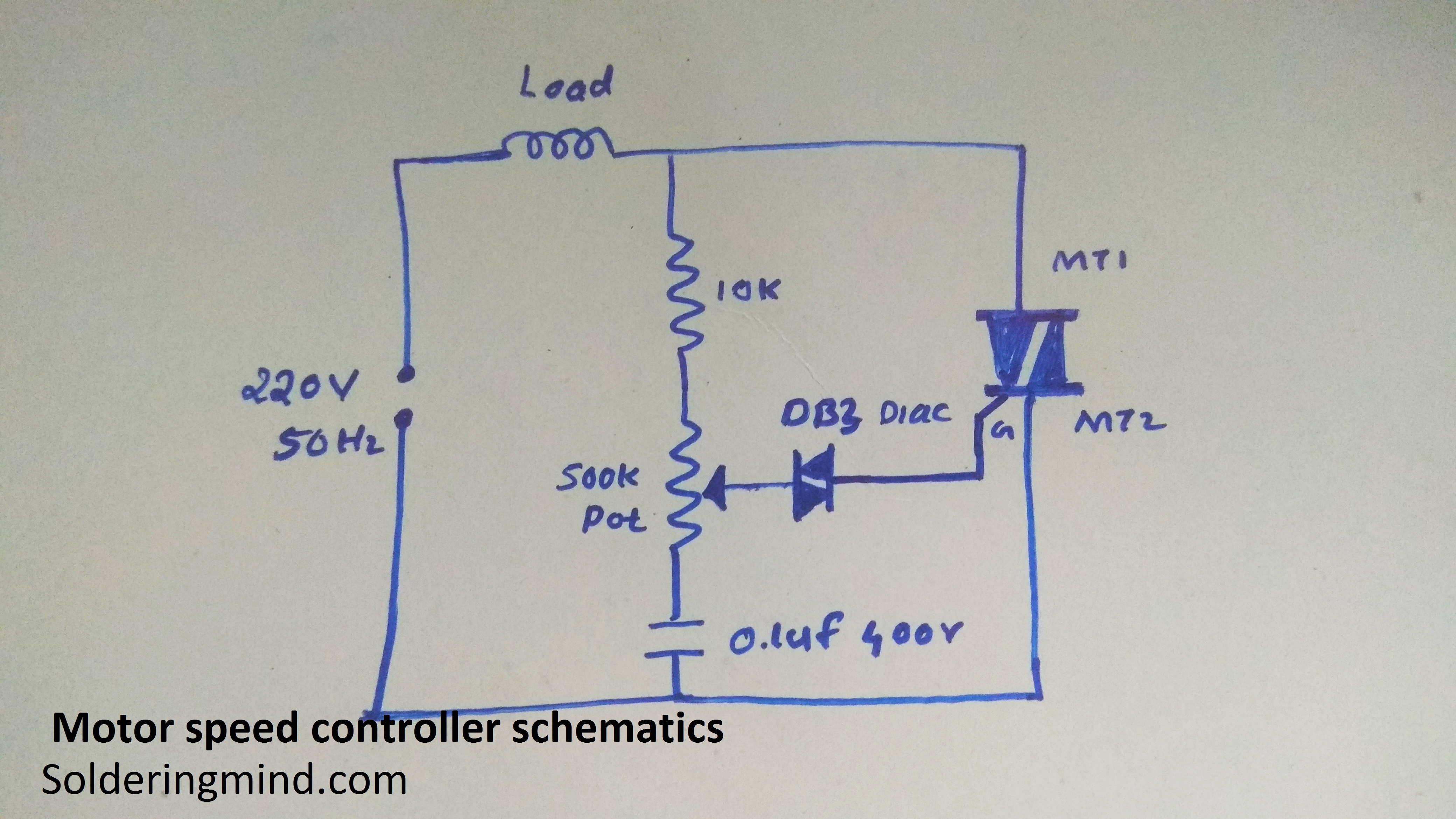

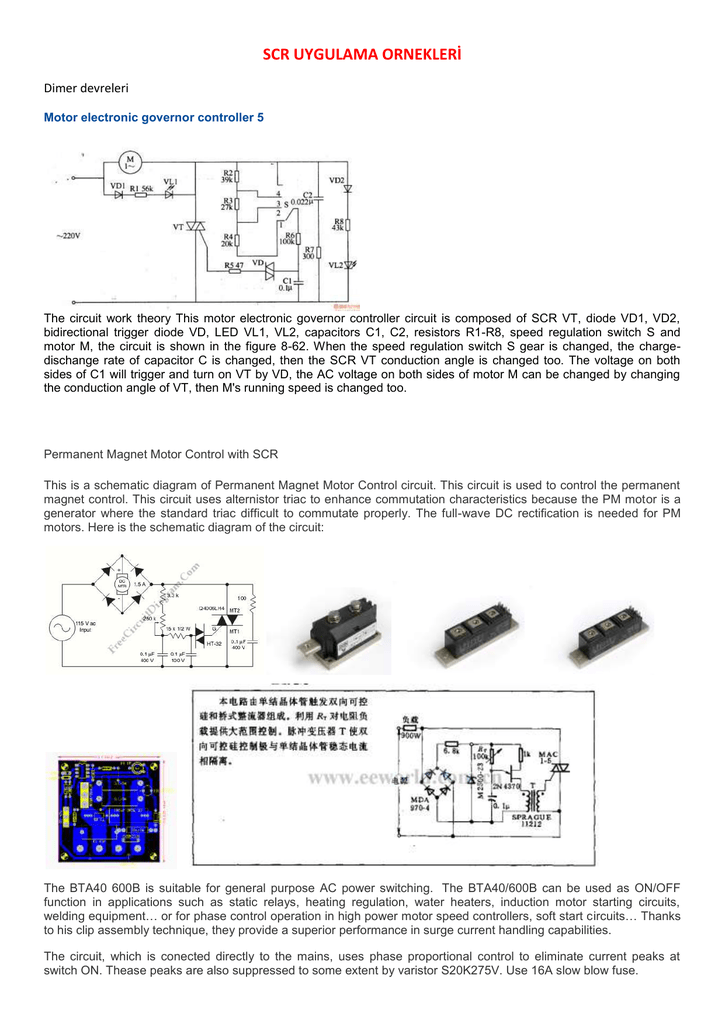

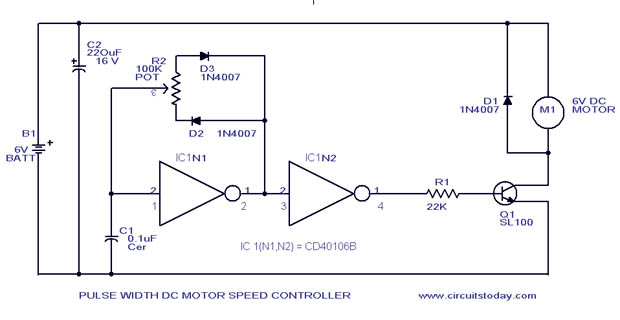

Induction motor speed control circuit diagram. Acpwm control system for induction motor. The circuit incorporates a self stabilizing technique that maintains the speed of the motor even when it is loaded. One contactor burnt for high speed and a replced contactor does not engange originally the coils re fed with a nutural and the one i replaced is only working with a phase. The setting of p1 determines the phase of the trigger pulse that fires the triac. Click here to view a capacitor start motor circuit diagram for starting a single phase motor. In the engine speed controller any transistors with an operating current of at least 250 ma and a.

This circuit is known as a latching circuit because it latches in the on state after a momentary action. Acpwm control for induction motor is a system that enables the single phase ac motor to run at different speeds. From the equation 1 it is clear that the motor speed can be changed by a change in frequency f a number of poles p and slip s. The rotor speed of an induction motor is given by the equation shown below. Wondering how a capacitor can be used to start a single phase motor. Learn how a capacitor start induction run motor is capable of producing twice as much torque of a split phase motor.

Also read about the speed torque characteristics of these motors along with its different types. Please help how to go about this. In market different speed control drives are available in which also pwm pulse width modulation techniques are used but they have low efficiency because they have higher order of harmonic content as well as their cost is also so much high. Speed control of an induction motor there is a various method of speed control of an induction motor. This type of motor requires low starting torque but needs to keep a constant torque while running. The no load current i 0 is simulated by a pure inductive reactor x 0 taking the magnetizing component i µ and a noninductive resistor r 0 carrying the core loss.

The speed of the motor can be controlled by changing the setting of p1. Kindly email me the diagrams for star deltor and direct online for a 3speed 1directon 3ph motor have two of them in a bow cutter. The device is designed to adjust the speed of an electric motor running on alternating current. The follow up question of how we may make the motor stop running is a. 220vac motor speed controller schematic. The stator circuit model of an induction motor consists of a stator phase winding resistance r 1 stator phase winding leakage reactance x 1 as shown in the circuit diagram below.

The old post triac based motor speed control if we avoid the pwm control section and power circuit use for just on and off for a low voltage three phase induction motor 100 volt to 150 volt frequently with help of a on off sensorin 100 or more voltagemotor too hot after some time runningif apply 50v three phase it will be working finebut. Capacitor run induction motor.