Sealed transmission couplings extend motor life by preventing mud contamination. Powerpak motors feature both oil sealed and mud lubricated bearings for rough drilling environments.

The Mud Motor Reducer

Drilling mud motor diagram. Six different drilling motors can be provided for bit sizes ranging from 4 ¾ in. Scientific drilling international designs engineers manufactures and operates one of the leading drilling mud motor portfolios in the industry. Nov downhole engineering can provide an air drilling performance chart if the following information. Lead by the titan motor platform scientific drilling internationals comprehensive suite of offerings is built for todays most complex and challenging drilling conditions. The pcpd pump uses drilling fluid commonly referred to as drilling mud or just mud to create eccentric motion in the power section of the motor which is transferred as concentric power to the drill bit. Manufacturer of downhole directional drilling tools and mud motor parts for the oil and gas industry.

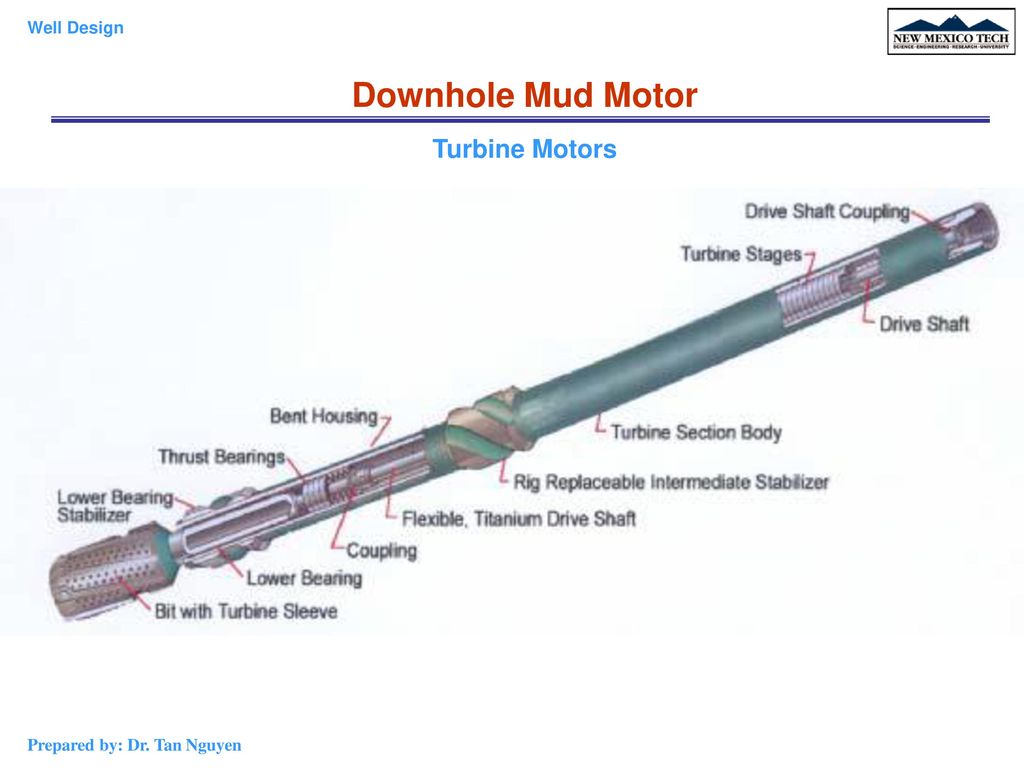

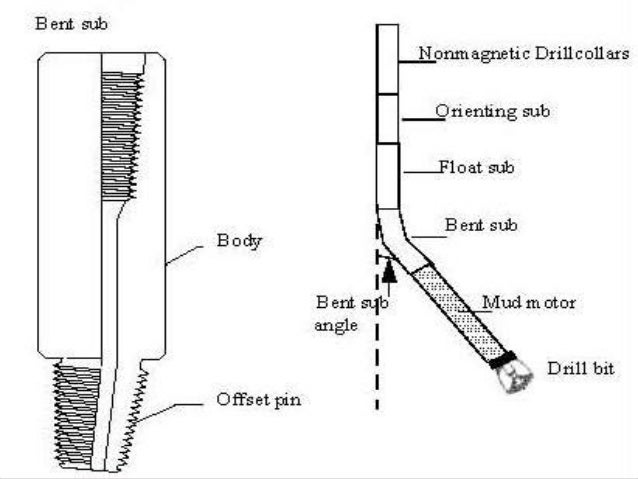

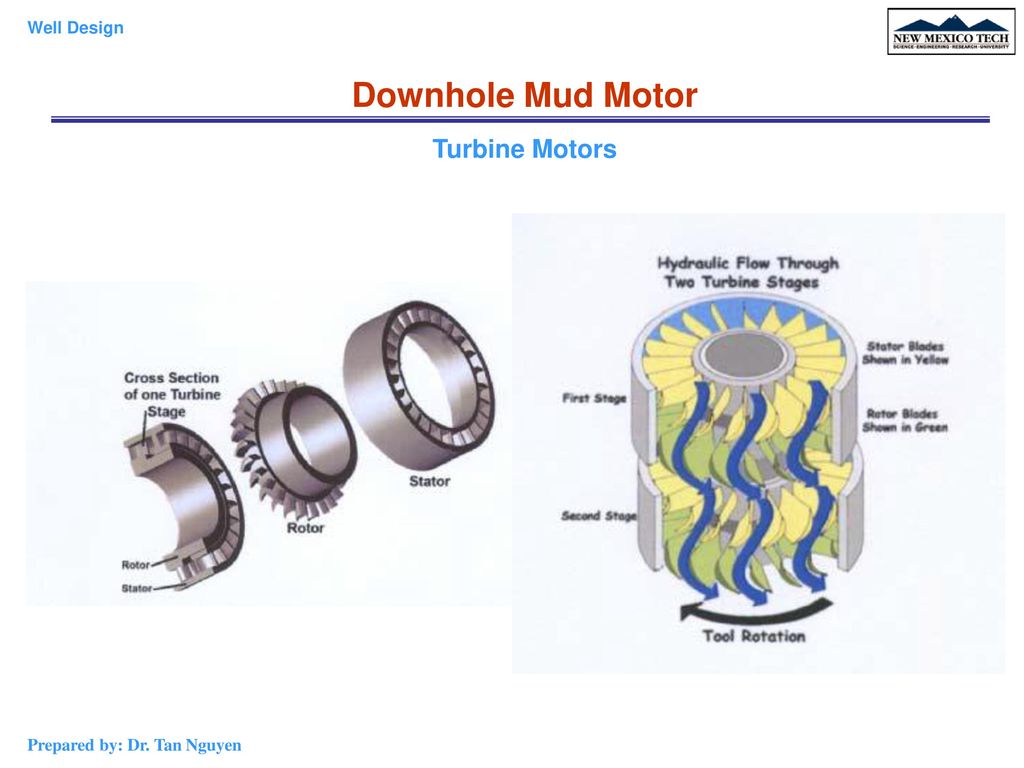

Hammer drilling is an alternative drilling method and drill bit type that conceptually replaces the downhole mud motor with a drilling fluid activated drilling hammer. Mud motors convert hydraulic energy from the drilling fluid into mechanical energy to turn the drill bit independent of the drill string. To 12 ¼ in. We leverage 30 years of drilling experience to combine the right torque speed and flow capabilities in our positive displacement mud motors. The hammer then compressively breaks up the rock at the bottom of the hole through rapid vertical up and down motion. Schematic diagram of mud motor.

This allows slower drill string rotational speeds which in turn equals more efficient drilling and less wear on the drill string and its components. N the variety of rotorstator configurations allows. As shown in table 1. N the mud lubricated bearing section is short and. A mud motor or drilling motor is a progressive cavity positive displacement pump pcpd placed in the drill string to provide additional power to the bit while drilling. The rotation rate of the bit is proportional to the volumetric flow rate of drilling mud through the motor and normal rotation rates are from 60 rpm to over 150 rpm.

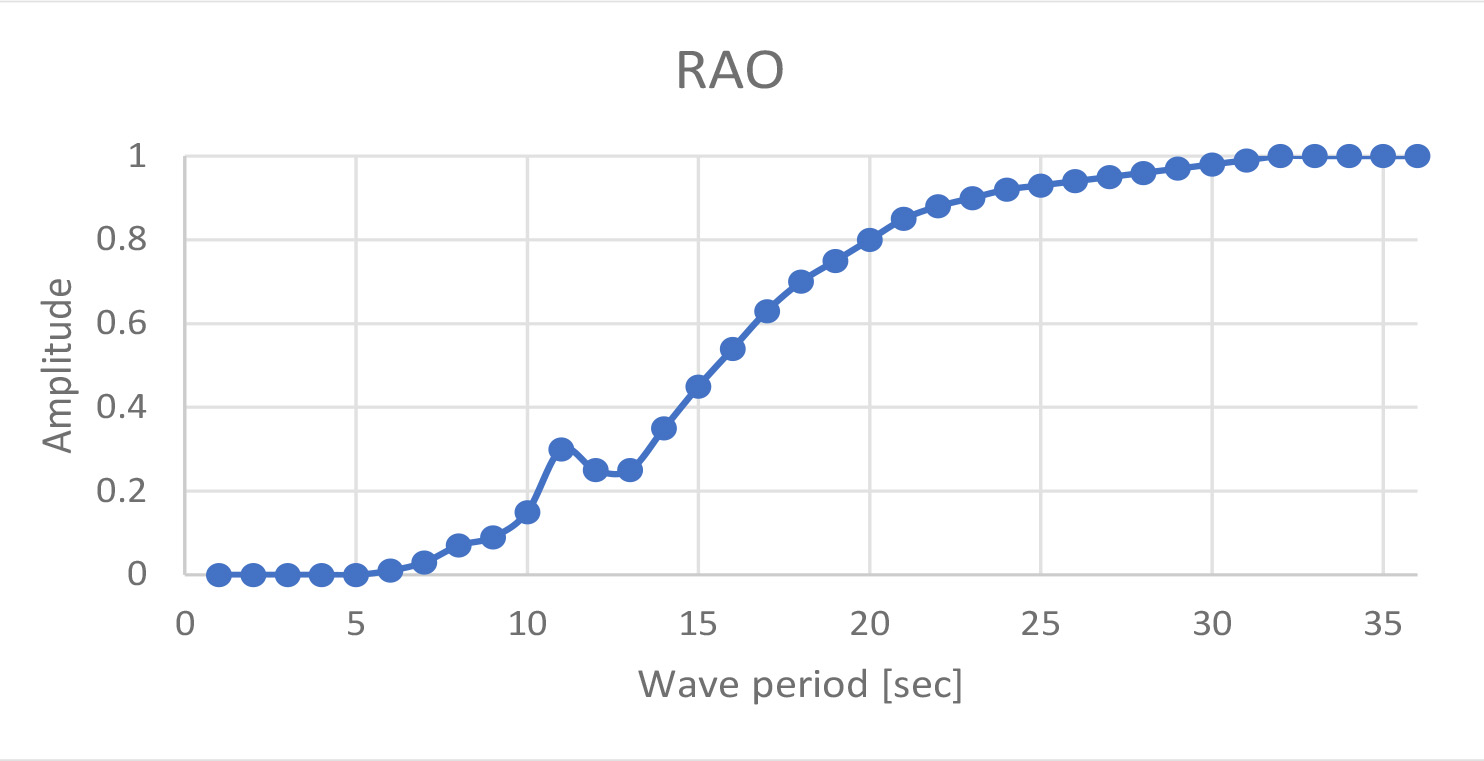

Motor handbook 7th edition performance curves the performance of a mud motor when run in an air drilling application is not as consistent across temperature and pressure ranges as when run with drilling mud due to the compressibility of the air. These motors maximize downhole power output which enables optimal bit performance and precise well steerability.