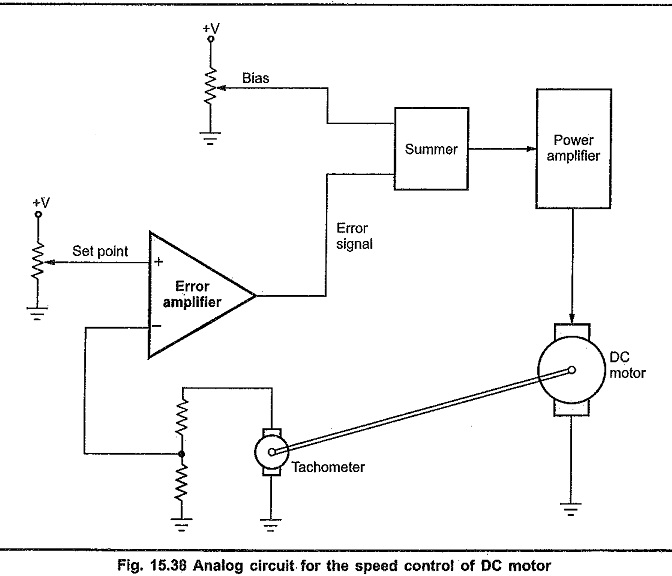

The magnetic poles of dc motor are structures fitted onto the inner wall of the yoke with screws. Block diagram of a typical brushless dc motor control or drive system is shown in the following image.

Dc Motor Basic Parts Electrical Machines Instrumentation

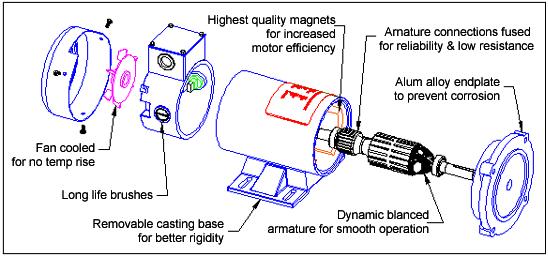

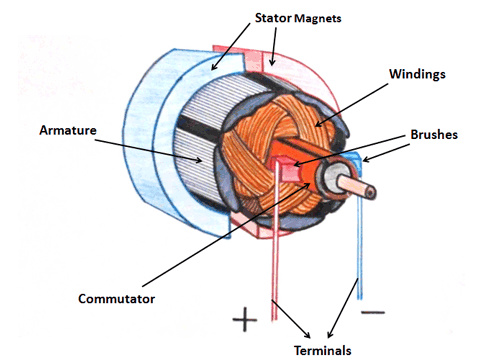

Dc motor diagram with parts. Poles of dc motor. 1 dc motor. One is a brushed dc motor and the other one is brushless dc motor. Electric motor designs can vary quite a lot though in general they have three main parts. The construction of magnetic poles basically comprises of two parts. Which is the rotating part.

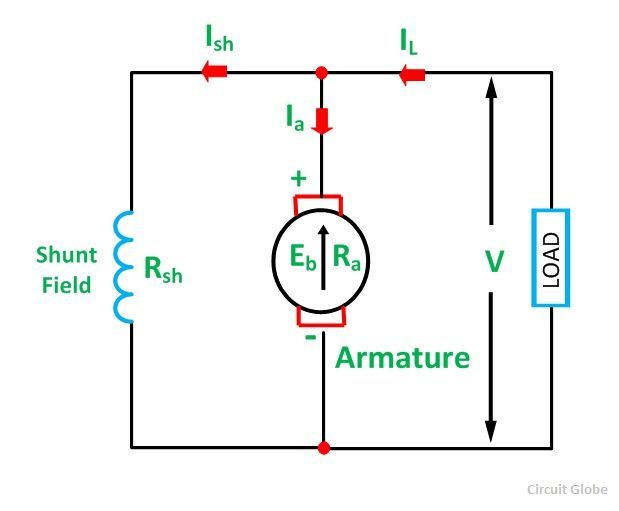

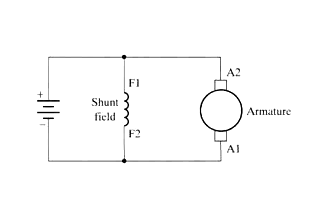

A rotor a stator and a commutator. Following is the schematic diagram of the dc motor interface to arduino uno board. 1 arduino uno. Namely the pole core and the pole shoe stacked together under hydraulic pressure and then attached to the yoke. Its the stationary part containing the field winding and receives the supply. Construction of dc motor nearly looks like the construction of dc generator originally when the dc machine starts working we cant identify whether its a dc generator or motor briefly dc motor consists of.

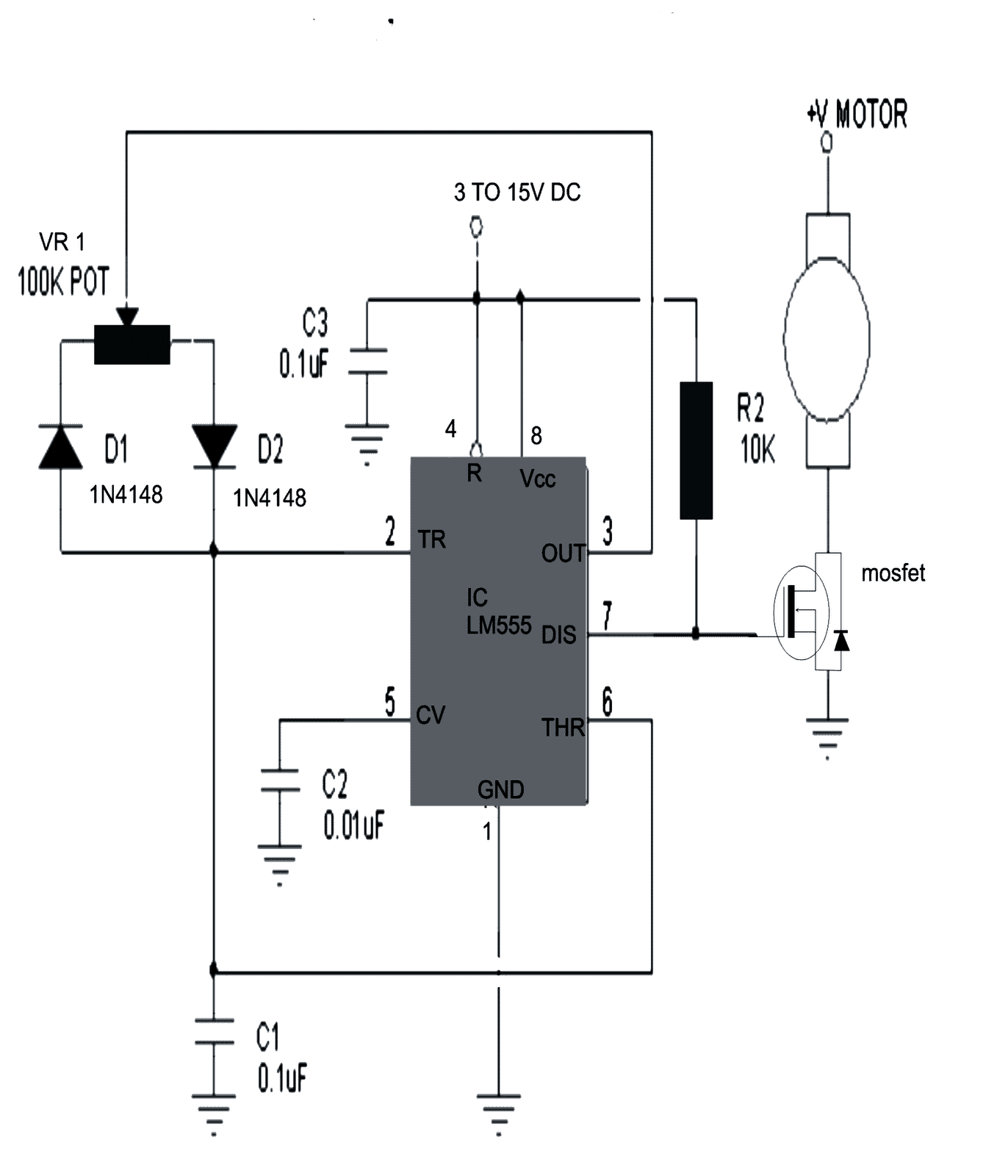

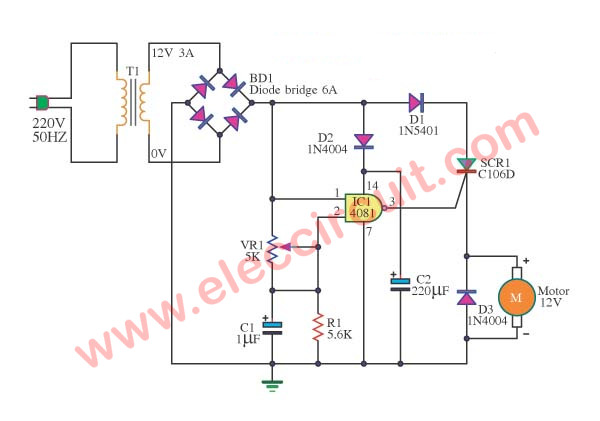

This drive circuitry is often known as electronic speed controller system or simply an esc. The cross section of a dc machine is shown in the figure below. The diagram given below represents the various parts of a dc machine. Brushed motors were the first commercially important application of electric power to driving mechanical energy and dc distribution systems were used for more than 100 years to operate motors in commercial and industrial buildings. Brushless dc motors are mainly used in high speed applications such as multicopters eg quadcopters. A dc motor is any of a class of rotary electrical motors that converts direct current electrical energy into mechanical energy.

These three parts use the attractive and repulsive forces of electromagnetism causing the motor to spin continually as long as it receives a steady flow of electric current. The most common types rely on the forces produced by magnetic fields. If stator and rotor are essential parts of a bldc motor that are integral to it then the driving electronics are equally essential. Nearly all types of dc motors have some internal mechanism either electromechanical or electronic to periodically change the direction of current in part of the motor. We have ac and dc motors small motors large motors tachometers carbon brushes and a full listing of motor parts available. We can supply new units to suit your needs renewal parts to rejuvenate legacy motors and recommended spares to keep on hand in the event of an unplanned outage.

The above diagram shows how to connect the l298 ic to control two motors. Construction of dc motor. Dc motors are of two types. A brushed dc electric motor is an internally commutated electric motor designed to be run from a direct current power source. 10 jumper wires.