Carbon brushes for electric motor repair are designed to increase brush life and surface contact to enhance performance. A carbon brush also known as a motor brush is the small part of the motor that conducts electrical current between the stationary wires stator and the rotating wires rotor of a motor or generator.

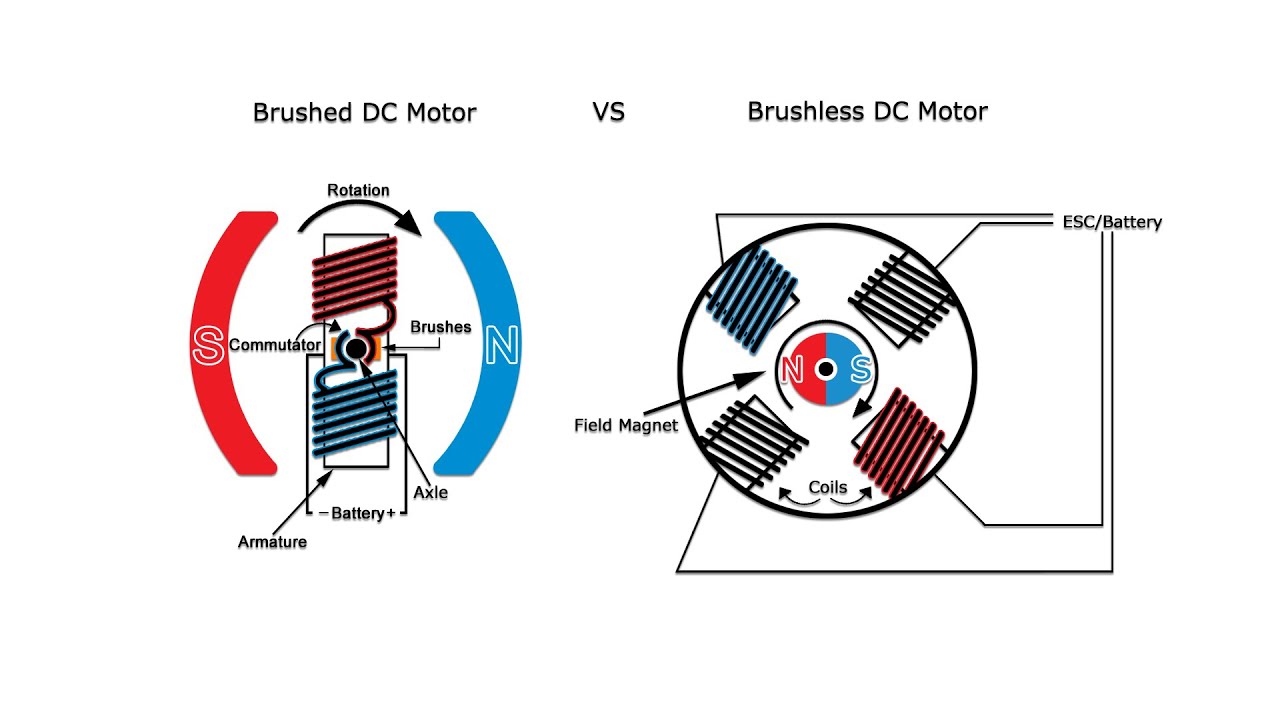

Brushed Vs Brushless

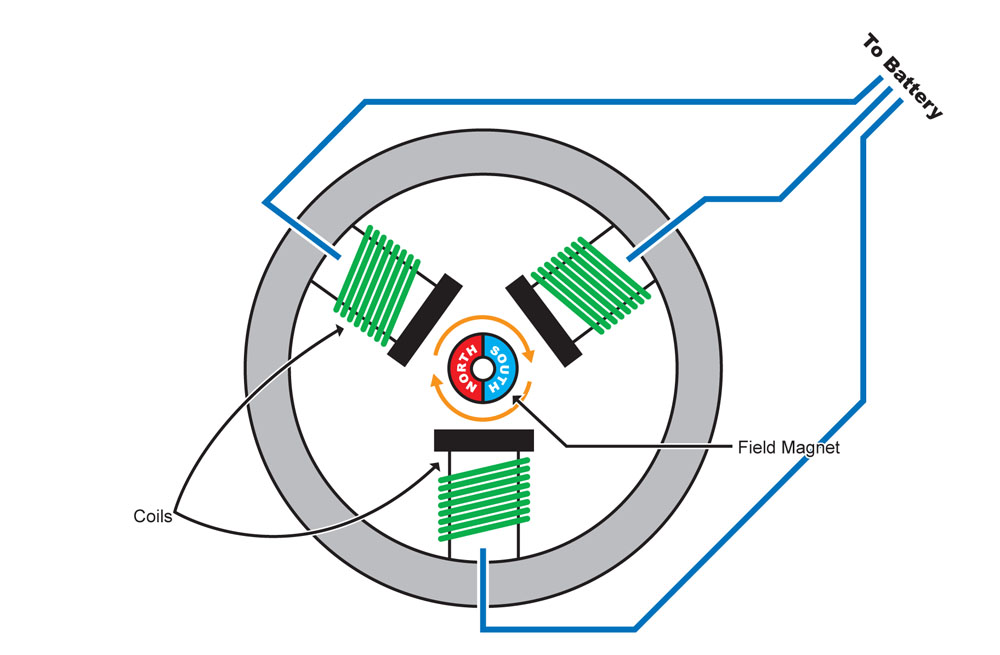

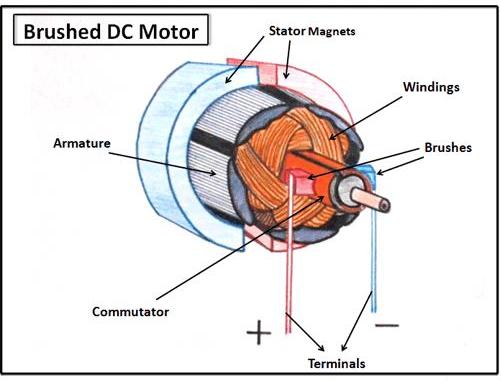

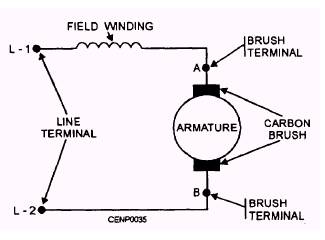

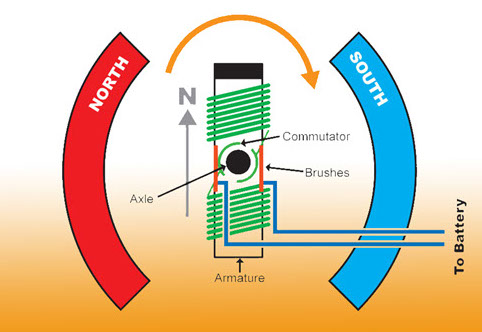

Brush motor diagram. The single phase series motor is an attempt to build a motor like a dc commutator motor. The brushes may also be lifted to prolong brush life. In a typical dc motor there are permanent magnets on the outside and a spinning armature on the inside. Commutator and brushes the diagram at the right shows how the commutator and brushes work together to let current flow to the electromagnet and also to flip the direction that the electrons are flowing at just the right moment. A brushed dc electric motor is an internally commutated electric motor designed to be run from a direct current power source. Commutator type motors these schematics are of commutator brush type ac and dc motors.

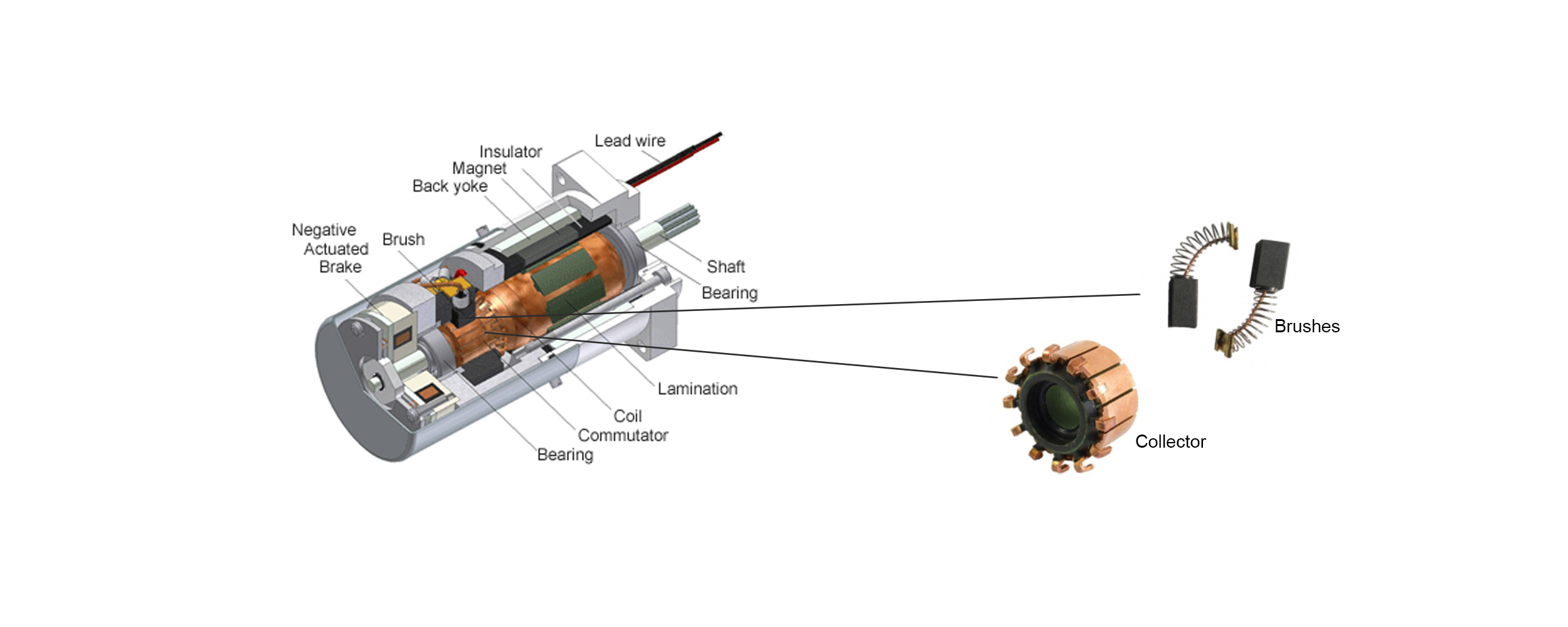

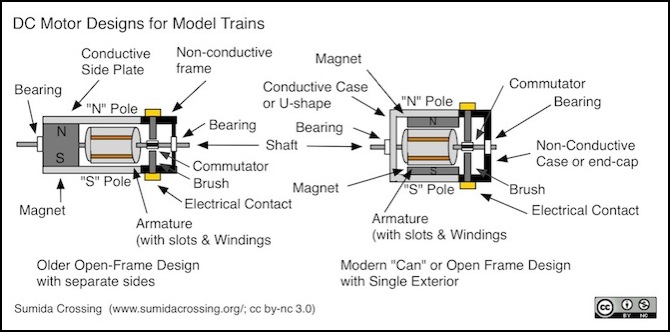

Stationary motor shaft and washers armature rotor commutator and sometimes a varistor and. The diagram below shows this layout in an exploded view of a typical dc motor in this case a small ø12mm vibration motor. Ac commutator motors fig. A motor generally contains more. The commutator and the brushes. Brushed motors were the first commercially important application of electric power to driving mechanical energy and dc distribution systems were used for more than 100 years to operate motors in commercial and industrial buildings.

The basic parts of a brushed dc motor are. Starting torque is 300 to 600 of the full speed value as compared to under 200 for a pure induction motor. The flipping the electric field part of an electric motor is accomplished by two parts. Brushes and terminals or leads. The armature contains an electromagnetwhen you run electricity into this electromagnet it creates a. The brush is typically made up of one or more carbon blocks and can come with one or more shunts or terminals.

Universal type compensated series connected ac motor circuit diagram. The resulting motor is only practical in the smallest sizes. Eis supplies various types of brushes and accessories such as. Case bearing and stator magnets stator ie. The permanent magnets are stationary so they are called the statorthe armature rotates so it is called the rotor. These brushes are typically found in dc motors generators slip ring motors motors and grounding applications.

The article how electric motors work explains how brushed motors work.