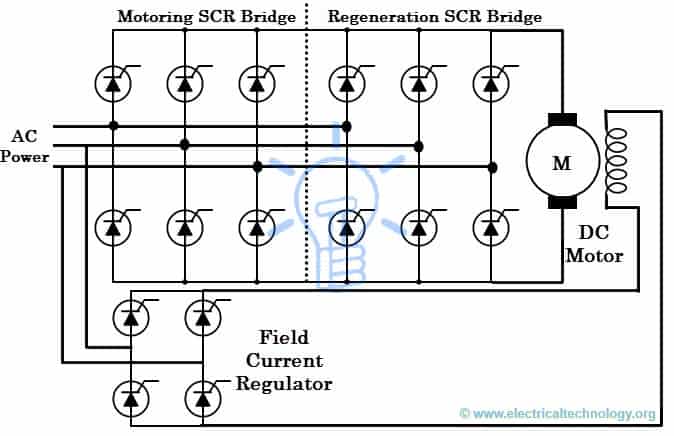

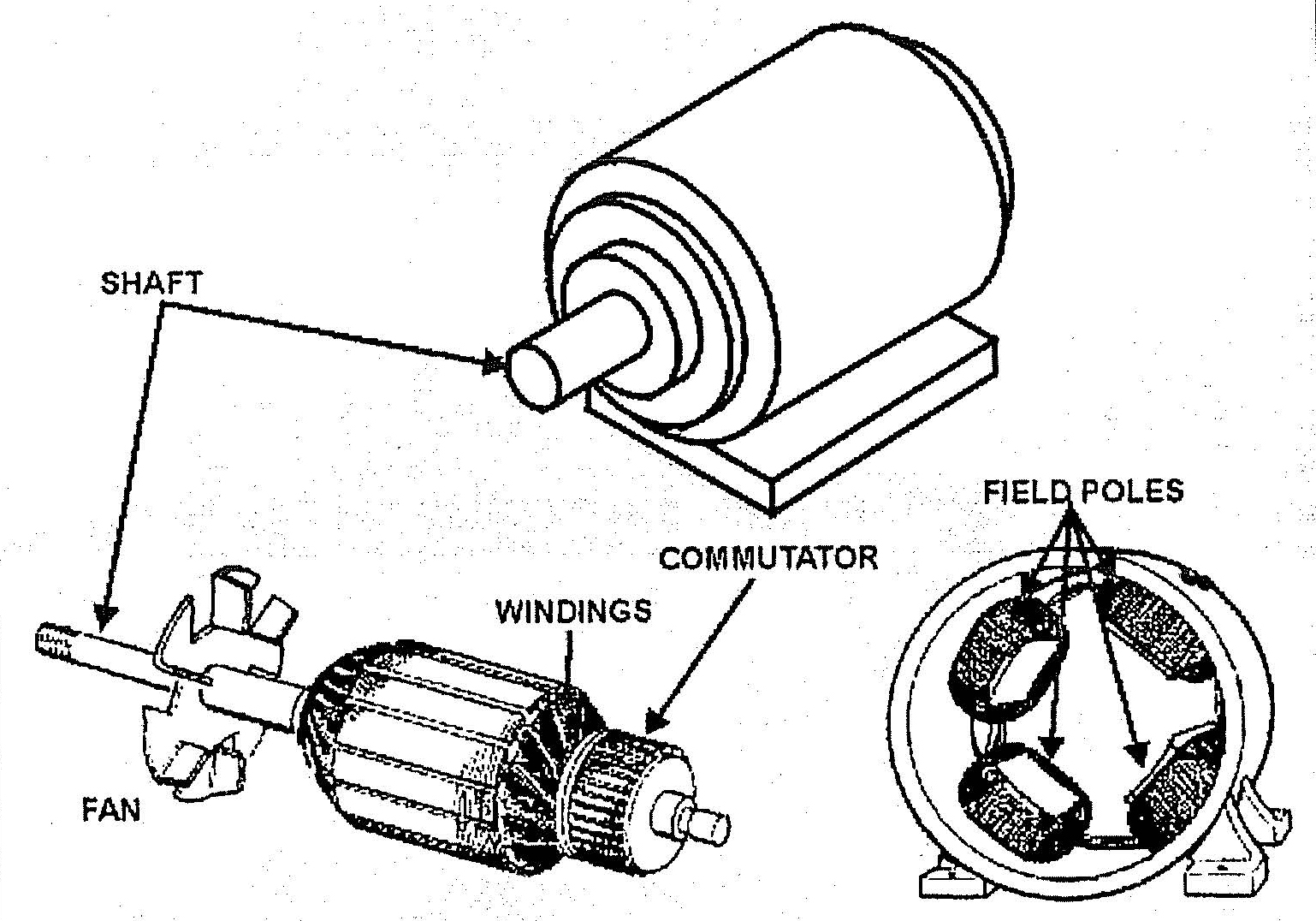

Applications of the motor usage of brushes and the maintenance cost of the motor. Brushed motors were the first commercially important application of electric power to driving mechanical energy and dc distribution systems were used for more than 100 years to operate motors in commercial and industrial buildings.

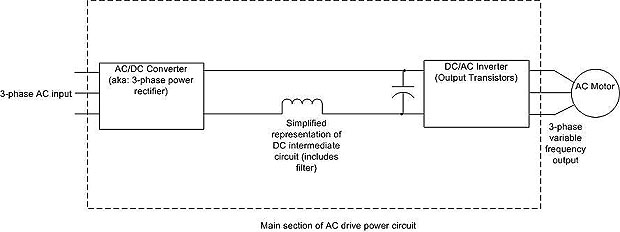

Dc Drive Block Diagram Explanation In Hindi

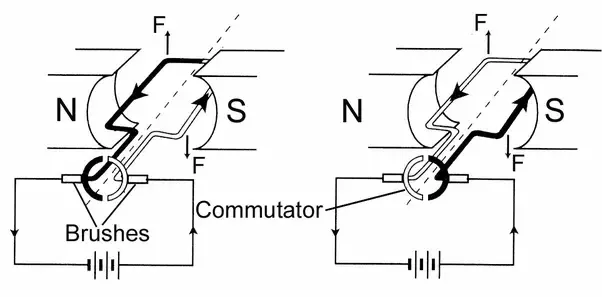

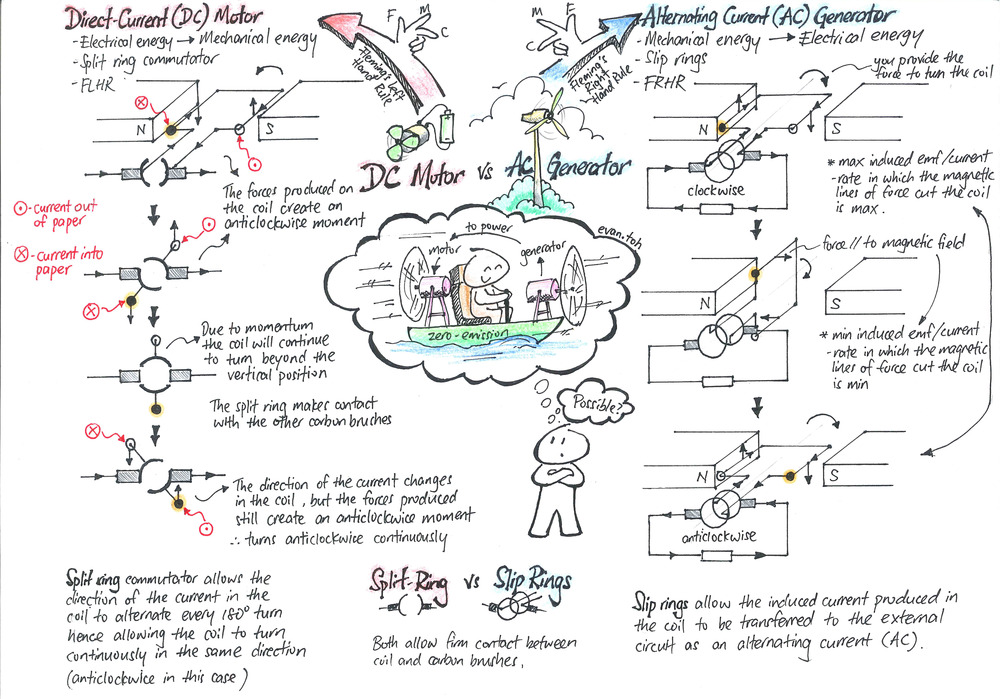

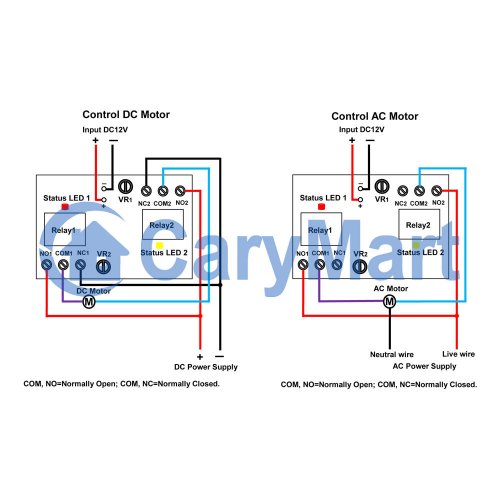

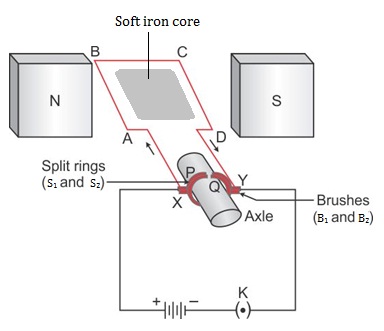

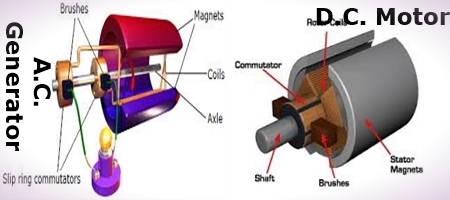

Ac and dc motor diagram. Although the ac motor has a simple structure the working principle is actually more complicated than that of the dc motor. Thus a negative slope provides viscous damping for the servo drive system. The commutation process types starting of the motor a number of terminals. A brushed dc electric motor is an internally commutated electric motor designed to be run from a direct current power source. The ac servo motors are divided into two types 2 and 3 phase ac servomotor. Difference between ac and dc motor the ac motor and the dc motor are differentiated on the various factors like the source or the nature of the power used in the motor.

If you want to understand clearly it will be more difficult. The two types of dc motors include. As from the above characteristics it is seen that the slope is negative. One of the oldest types of motor brushed motors are internally commutated electric motors. An ac motor uses alternating current in other words the direction of current flow changes periodically. The torque speed characteristics of the motor is shown below.

In the case of common ac that is used throughout most of the united states the current flow changes direction 120 times every second. A three phase symmetrical alternating current is applied to the stator of the ac motor as shown in the figure above. Dc motors are made up of several parts the most notable of which include bearings shafts and a gearbox or gears. An ac motor converts electric energy into mechanical energy. Dc motors offer better speed variation and control and produce more torque than ac motors.